Dampers

Instruction

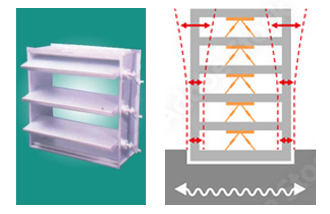

Louvers / flap are made of mild steel / galvanised

sheet. The louvers / flap are designed in the form, which can withstand high

temperature control in closed position to the flame path between air duct and fire

effected area.

The shape of the louvers / flap in somewhat complex in nature

for multi fold purpose.

i) The complex shape reduces the leakage facto

considerably.

ii) Five exposed surfaces are backed up

Positive sealing

linkage

Linkage provided with spring return devices for positive setup pressure on each louvers / flap, enabling reduction in leakage factor.

Sealing System : Complex shape are provided at mating surfaces are designed to creat a heavy pressure drop during leakage, because the air / gas has to take two sharp angles turns. This gives a low leakage factor during damper operation.

Sealing efficiency : The ceiling of damper is 97% on cross sectional area.

Closing Reliability : BKA Fire Dampers are designed to close automatically

immediately (depends on mode of actuation) on receive of signal of fire

occurance.

Accessories (Optional)

1. Position Transmitter

2. "Open"

and / or "Close" indication

3. Auxiliary Switches